.

.

About Iranian Trading Company is widely known as a prominent Sulfur and Granular Sulfur Supplier to India, China, and some other Asian and African countries for more than one decade.

Exporting over half a million MT of Sulphur proves the reliability and validity of our company in this regard. Amoot Iranian is a customer-oriented company that does its best to gain credit by paying attention to all its customers’ needs and preferences in terms of shape (Flakes, Granular, or Lump), packing (bulk or Jumbo/big bags). Amoot Iranian tries to make its customers’ increase their production efficiency by supplying the best quality Sulphur along with delivering it with its initial quality maintained. With all the experience attained in Sulphur logistics including purchase, loading, shipping, discharging, packing and etc.

Amoot Iranian staff is fully aware of the possible issues which may harm Sulphur quality since production until being delivered to the end-user, hence Amoot Iranian considers and implements all the relative concerns to avoid them. Sulfur is a chemical nonmetallic element.

At room temperature, it is normally bright yellow, light solid with an unpleasant smell. When reacting with hydrogen it smells like a rotten egg. It is insoluble in water.

Sulfur may be originated from minerals or gas and oil. Previously Sulphur was mainly extracted from salt domes until the late twentieth century. Today Sulphur is mainly derived as a side product of the oil and gas refining process which is mostly in form of H2S known as hydrogen sulfide.

Another major Sulphur containing impurity in petroleum are the organoSulphur compounds which may be hydrode Sulphurized and yield hydrogen sulfide. This Hydrogen sulfide undergoes the Claus Process in which hydrogen sulfide is oxidized to Sulphur oxide and then again the Sulphur oxide reacts with some other hydrogen sulfide and results in final products: Sulphur and water.

Granular Sulphur manufacturers

Granular sulfur is a versatile and essential raw material used in a wide range of industries, including agriculture, chemical manufacturing, and oil refining. It is a yellow, odorless, and tasteless solid that is derived from elemental sulfur. The granular form of sulfur is preferred due to its ease of handling, storage, and transportation. The increasing demand for granular sulfur has led to the growth of numerous manufacturers around the world.

Granular sulfur is used as a soil amendment to lower soil pH, increase soil fertility, and improve plant growth. In agriculture, it is an essential ingredient in the production of fertilizers, helping to improve soil fertility and increase crop yields. In the chemical industry, granular sulfur is used as a feedstock for producing sulfuric acid, a key ingredient in many chemical processes. In the oil refining industry, granular sulfur is used to reduce the sulfur content in petroleum products.

Manufacturers of granular sulfur are located in different parts of the world, including North America, Europe, Asia, and the Middle East. Some of the leading granular sulfur manufacturers include:

| Sulfur Supplier | Logo | Description |

|---|---|---|

| The Mosaic Company | Based in the United States, is a leading producer of fertilizer and animal feed products. The company also produces granular sulfur, which is used as a soil amendment and in the production of fertilizers. | |

| OCP Group | Based in Morocco, is one of the largest producers of fertilizers and other agricultural products in the world. The company produces granular sulfur as a key ingredient in its fertilizers. | |

| Yara International | Based in Norway, is a leading producer of fertilizers, industrial products, and environmental solutions. The company produces granular sulfur as a soil amendment and as a key ingredient in the production of fertilizers. | |

| Amoot Iranian | Based in Iran, is a leading supplier of high-quality granular sulfur in the Middle East. With a team of experienced professionals, the company is committed to providing its customers with high-quality products and excellent customer service. |

The manufacturing process of granular sulfur involves melting elemental sulfur and then cooling it to form small granules. The granules are then dried, screened, and packaged for distribution. The quality of granular sulfur is critical to its performance, and manufacturers must adhere to strict quality control measures to ensure that their products meet customer specifications.

When selecting a granular sulfur manufacturer, it is important to consider factors such as product quality, reliability, and customer service.

In addition, it is important to select a manufacturer that is committed to sustainable practices and environmental responsibility. Many manufacturers are now using environmentally friendly production methods, such as reducing their carbon footprint and using renewable energy sources.

Granular sulfur is a vital raw material that plays a critical role in many industries. With the growth of the global population and the increasing demand for food, it is expected that the demand for granular sulfur will continue to grow in the coming years.

As a result, manufacturers are investing in research and development to develop new and innovative products to meet the needs of their customers.

In conclusion, granular sulfur is an essential raw material that is used in a wide range of industries.

With the increasing demand for high-quality granular sulfur, manufacturers around the world are working to provide their customers with products that meet their needs and expectations. Whether you are looking for a soil amendment, a key ingredient in fertilizers, or a raw material for chemical production, a reliable and high-quality granular sulfur manufacturer can help you achieve your goals.

.

Sulfur Applications

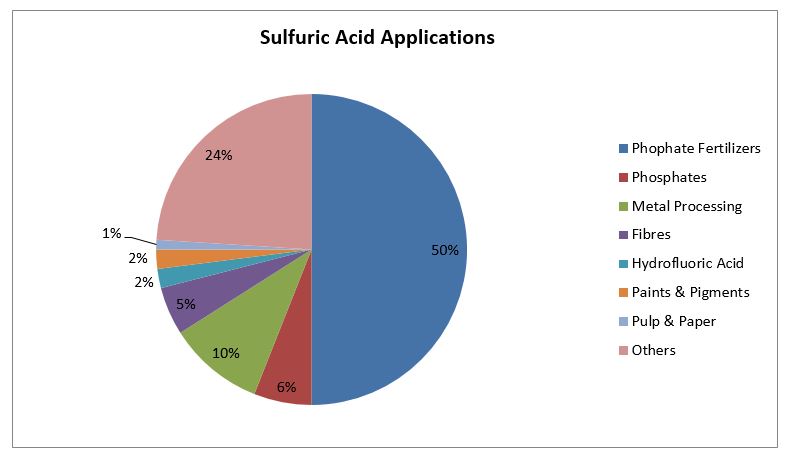

Sulfur is widely used as raw material in numerous applications: Sulphuric Acid, Fertilizers, pharmaceuticals, Bactericide in winemaking and food preservation, and Sulphur inlay in types of furniture.

Fertilizer: Every day the fertilizers composed of Sulphur are increasing. The most important Sulphur containing fertilizer is mineral calcium sulfate.

As elemental Sulphur’s hydrophobicity does not let it be used directly by plants. Soil bacteria can convert it to derivatives that are soluble that is can then be consumed by plants. Sulfur improves the efficiency of other vital plant nutrients, especially nitrogen and phosphorus.

Biologically produced Sulphur particles are naturally hydrophilic due to a biopolymer coating, they are easier to disperse over the land in a spray of diluted slurry, which results in a faster uptake.

The botanical requirement for Sulphur equals or even exceeds the requirement for phosphorus. It is an essential nutrient for plant growth, root nodule formation of legumes, and immunity and defense systems. Sulfur deficiency has become widespread in many countries in Europe.

As atmospheric intake of Sulphur decreases continually, the deficit in the Sulphur input/output is more probable to increase unless Sulphur fertilizers are used.

Sulfur is Known and applied from thousand years ago. It has a varied range of uses so that in the past, sulfur consumption performed as an indicator that demonstrated the industrial activities of a country.

One of its main and primary applications is acid sulfuric production that is useful to produce organic chemicals, minerals, and mainly agricultural fertilizers. Also, sulfur is used to produce explosive materials, rayon, reagents, color emollients, tires, matches, phosphate fertilizers, asphalt, sulfuric concrete, nitrogen fertilizers like ammonium sulfate and etc.

Sulphuric Acid: Sulphur, as an element, is mainly applied to produce Sulphuric Acid. Sulphuric acid is a very important commodity chemical, and indeed, a nation’s Sulphuric acid production is a good indicator of its industrial strength.

World production in 2004 was about 180 million MT, with Asia 35%, North America 24%, Africa 11%, Western Europe 10%, Eastern Europe and Russia 10%, Australia and Oceania 7%, South America 7%.

The major principal application of Acid Sulphuric is extracting phosphate ores to produce fertilizers. Approximate 60% of the Sulphuric Acid market belongs to chemical fertilizers production. Other applications include the refining process of oil, wastewater processing, and extraction of minerals.

That is why only in the US in 2010, Sulphuric acid was produced more than any other inorganic industrial chemical. About 20% is used in the chemical industry for the production of detergents, synthetic resins, dyestuffs, pharmaceuticals, petroleum catalysts, insecticides, and antifreeze, as well as in various processes such as oil well acidizing, aluminum reduction, paper sizing, water treatment.

About 6% of uses are related to pigments and include paints, enamels, printing inks, coated fabrics, and paper, and the rest is dispersed into a multitude of applications such as the production of explosives, cellophane, acetate and viscose textiles, lubricants, non-ferrous metals, and batteries.

.

Turkmenistan Sulfur Manufactures

Turkmenistan is a country with abundant natural resources, including sulfur. Sulfur is an essential raw material used in a wide range of industries, including agriculture, chemical manufacturing, and oil refining. In recent years, Turkmenistan has become a major producer and supplier of high-quality sulfur, making it an important player in the global sulfur market.

.

- Product: Turkmenistan Granular Sulfur 99.95%

- Packaging : Big bag 1 MT

- Price : Negotiable

- Terms : Negotiable, CFR , FOB

- Min order : 1000 MT

- Origin : Turkmenistan

Turkmenistan is known for its rich deposits of elemental sulfur, which is the raw material used to produce granular sulfur. The country’s sulfur mines are among the largest in the world, and they provide a reliable and cost-effective source of high-quality sulfur. This has helped to make Turkmenistan a major exporter of sulfur and a key supplier to the global market.

The manufacturing process of granular sulfur in Turkmenistan involves melting elemental sulfur and then cooling it to form small granules. The granules are then dried, screened, and packaged for distribution. The quality of granular sulfur is critical to its performance, and Turkmenistan’s manufacturers must adhere to strict quality control measures to ensure that their products meet customer specifications.

Turkmenistan’s sulfur manufacturers are dedicated to providing their customers with high-quality products and excellent customer service.

They work closely with their customers to understand their unique requirements and provide tailored solutions to meet their needs. The country’s manufacturers are also committed to sustainable practices and environmental responsibility, and many are using environmentally friendly production methods to reduce their carbon footprint and support the environment.

In conclusion, Turkmenistan is a major producer and supplier of high-quality sulfur, and its manufacturers are dedicated to providing their customers with products that meet their needs and expectations.

Whether you are looking for a soil amendment, a key ingredient in fertilizers, or a raw material for chemical production, Turkmenistan’s sulfur manufacturers are well positioned to meet your needs. So if you are looking for a reliable and cost-effective source of high-quality sulfur, consider working with Turkmenistan’s leading sulfur manufacturers.

.

Turkmenistan Granular Sulfur Specifications

| Description of Index | Spec. |

|---|---|

| Mass fraction of sulfur, %, : not less than | 99.95 |

| Mass fraction of ash, %, not less than | 0.03 |

| Mass fraction of organic compounds, %, not more than | 0.03 |

| Mass fraction of acids converted to sulfuric acid, %, not more than | 0.003 |

| Mass fraction of moisture, %, not more than | 0.2 |

| Presence of mechanical impurities | absent |

| Color | Bright Yello |

.

Chemical Fertilizers

The consumption growth rate of Sulphuric acid in the United States in 1985-1997 was only 2.2% which raised to 3.9% in 1997-2004. Acid Sulphuric is the key raw material in the production of Phosphoric Acid, Ammonium Sulphate fertilizers, and normal superphosphate, whereas phosphoric acid itself is the raw material in phosphate fertilizers’ production process.

Phosphoric Acid: the major process in which Sulphuric acid is required for phosphoric acid production is Wet Process.

In this process, phosphate rock is used, and more than 100 million MT are processed annually. This raw material is shown as fluorapatite, though the exact composition may vary. This is treated with 93% Sulphuric acid to produce calcium sulfate, hydrogen fluoride (HF), and phosphoric acid.

The HF is removed as hydrofluoric acid. Other phosphoric acid types which is the furnace type, do not require Sulphuric acid. In recent years due to the wet process of phosphoric acid’s massive production, this phosphoric acid is purified in another process and used instead of the furnace of phosphoric acid, either. Hence, the Sulphuric acid market is directly affected by phosphoric acid and its relative fertilizers production.

Ammonium sulfate, a key nitrogen fertilizer, is majorly produced as a byproduct from coking plants to supply the iron and steel-making plants.

Its reacting the ammonia produced in the thermal decomposition of coal with waste Sulphuric acid allows the ammonia to be crystallized out as a salt (often brown due to iron contamination) and sold into the agrochemical industries.

.

One other important application of Sulphuric acid is in manufacturing aluminum sulfate, also called paper maker’s alum. This can react with small amounts of soap on paper pulp fibers to give gelatinous aluminum carboxylates, which help coagulate the pulp fibers into a hard paper surface.

It is also used for making aluminum hydroxide that is used at water treatment plants to filter out impurities, as well as to improve the taste of the water. Aluminum sulfate is made by reacting bauxite with Sulphuric acid.

Sulphuric acid is also important in the manufacturing of dyestuffs solutions.

Sulfur–iodine cycle: This is a series of thermochemical processes used to yield hydrogen. It consists of three chemical reactions which net reactant is water and the net products are hydrogen and oxygen. The first step of the cycle is called the Bunsen reaction, where the Sulphur and iodine compounds are recovered to be reused, hence the process is referred to as a cycle.

.

The Sulphur–iodine cycle has been proposed as a way to supply hydrogen for a hydrogen-based economy.

Industrial cleaning agent: Sulphuric acid is widely used in the iron and steelmaking industry to remove oxidation, rust, and scaling from rolled sheets and billets prior to sale to the automobile and major appliances industry.

Used acid is often recycled through a spent acid regeneration (SAR) plant.

SAR plants are commonly added to metal smelting plants, oil refineries, and other industries where Sulphuric acid is consumed in bulk, since operating a SAR plant is way cheaper than the recurring costs of spent acid disposal and new acid purchase.

Catalyst: Sulphuric acid is used for various other purposes in the chemical industry. For instance, it is the usual acid catalyst for the conversion of cyclohexanone oxime to caprolactam, used for making nylon. It is used for making hydrochloric acid from salt via the Mannheim process. Much H2SO4 is used in petroleum refining, as a catalyst for the reaction of isobutane with isobutylene to give isooctane, a compound that improves the octane rating of gasoline (petrol).

Sulphuric acid is also often used as a dehydrating or oxidizing agent in industrial reactions, such as the dehydration of various sugars to form solid carbon.

Electrolyte: Acidic drain cleaners usually contain Sulphuric acid at a high concentration which turns a piece of pH paper red and chars it instantly, demonstrating both the strong acidic nature and dehydrating property.

Sulphuric acid acts as the electrolyte in lead-acid batteries (lead-acid accumulator).

An acidic drain cleaner can be used to dissolve grease, hair, and even tissue paper inside water pipes.

Domestic uses: High concentration Sulphuric acid is commonly the major ingredient of acidic drain cleaners or openers used to remove grease, hair, tissue paper, etc.

Like their alkaline types, such drain openers can dissolve fats and proteins through hydrolysis. Moreover, as concentrated Sulphuric acid has a strong dehydrating property, it can also remove tissue paper via dehydration.

.

Strategic Significance of Sulphuric Acid

As further discussed, the major application of Sulphuric Acid is in the production of phosphate fertilizers. Hence this makes the strategic significance of Sulphuric Acid.

The increasing population growth rate and limited agricultural lands increase the necessity of improving production efficiency per land unit. In order to be able to be responsible for population growth, organic fertilizers are no more applicable.

.

Organic fertilizers only improve the dust’s physical properties and make it ready for plant growth and it is still poor in nutrition. To improve efficiency, using chemical fertilizers is a must which necessity is completely discovered.

Sulphuric Acid is widely used in phosphate fertilizers and ammonium sulfate fertilizers and since it is not replaceable with any other materials, its significance is emphasized.

.

Major Producers and Consumers of Sulphuric Acid

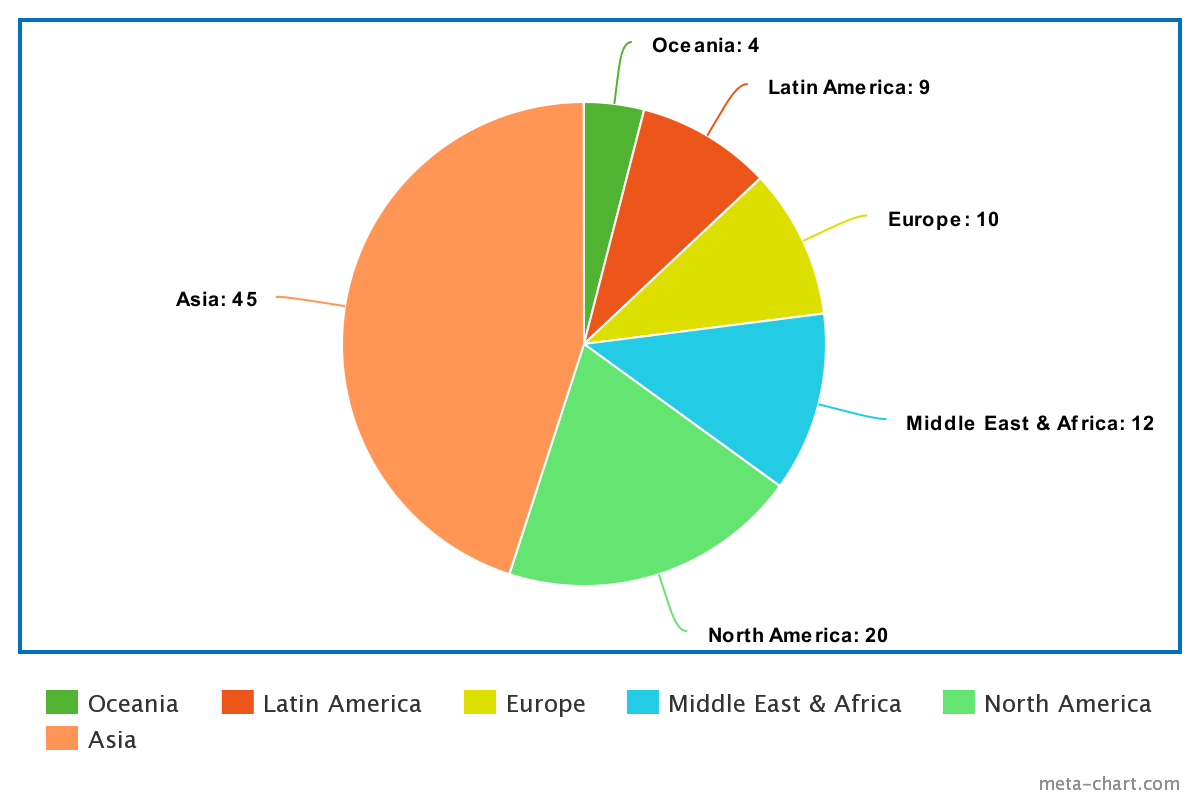

In 2012, the world Sulphuric acid capacity was estimated at more than 290.7 million tonnes. In the same year, Asia accounted for over 46% of the total capacity.

.

Sulphuric acid: structure of the world capacity by region, 2012

.

Mosaic Co, OCP Group, PotashCorp, Vale Limited, Groupe Chimique Tunisien, Codelco, Maaden, Rhodia Inc, Xstrata, Aurubis, OJSC «Ammofos», Oswal Greentech Limited, and CF Industries, among others, take the lead in the global Sulphuric acid universe.

The worldwide market for Sulphuric acid witnessed stable growth between 2009 – 2012, supported by increasing demand from major end-use industries. In 2012, Sulphuric acid production grew by more than 7 million tons and exceeded 230.7 million tons.

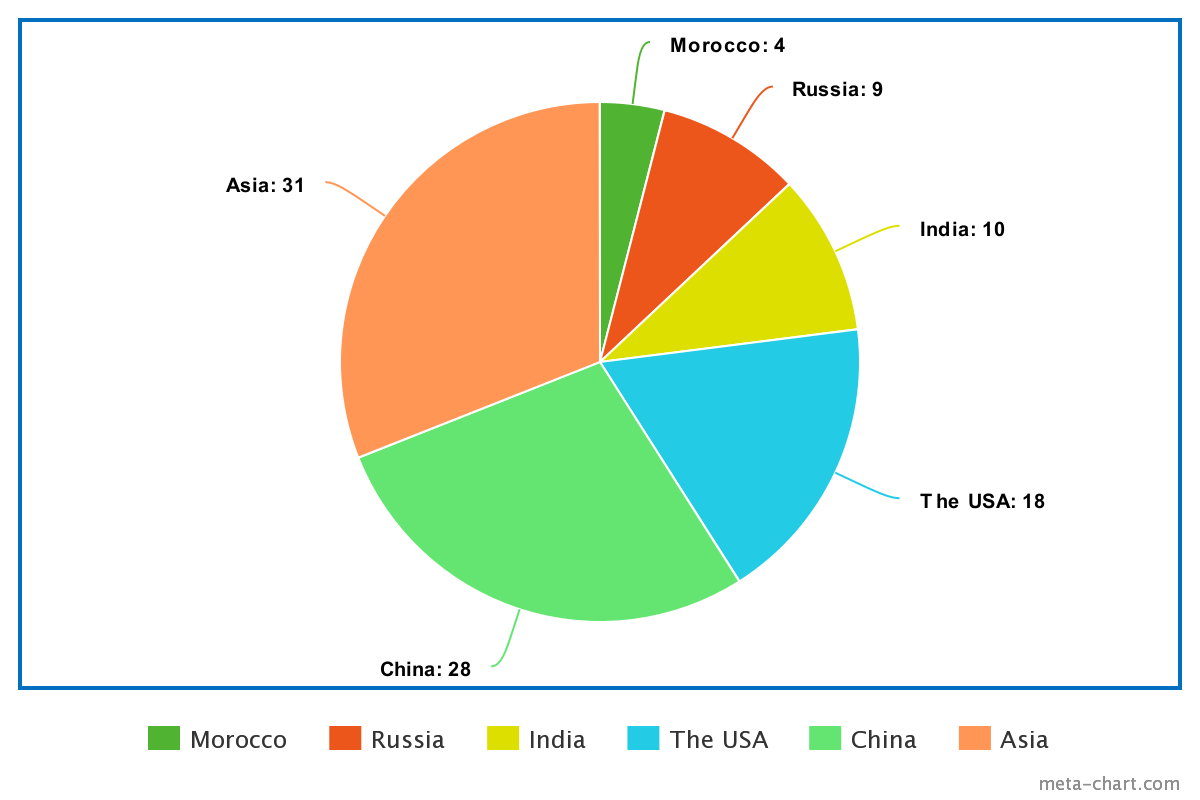

Asia ranks as the leading Sulphuric acid manufacturer, accounting for around 45% of the overall production. China, the US, India, Russia, and Morocco are the top five Sulphuric acid manufacturing countries.

.

Sulphuric acid: the world production by country, 2012

.

In 2012, its consumption volume surpassed the 106 million mark. The fertilizer industry is the product’s major end-use sector, consuming over 55% of the overall Sulphuric acid output.

In 2011, the world foreign trade in Sulphuric acid was valued at more than USD 1.87 billion. Europe is the leading Sulphuric acid exporter, whilst Asia is a market leader in terms of imports.

.

Opportunities and Major Players

Furthermore, the growing application in the healthcare industry for skin treatment procedures, such as the elimination of acne and manufacturing of medications associated with the treatment of dandruff and others will provide numerous opportunities for the growth of this market.

Some of the major players dominating the global market are –

- Abu Dhabi National Oil Company

- Guangzhou Petrochemical

- Sinopec Corp.

- OAO Gazprom

.

China, the Leading Sulphur Importer

China as the second-largest producer of Sulphur in all forms globally, is the world’s leading producer of pyrites, with about 57% of its Sulphur in all forms coming from that source.

The country is the leading Sulphur importer, representing about 35% of the global imports, the bulk of which is used to manufacture Sulphuric acid.

Energy production in China has been rising in recent decades across the oil & gas sector, leading to a boost in the domestic Sulphur recovery.

Furthermore, fertilizer production consumes about two-thirds of the Sulphuric acid consumption in China. In 2014, the government of China loosened the restrictions imposed on the fertilizer industry, which is further estimated to have boosted the fertilizers market.

Favorable policies towards fertilizers and the increasing energy production are likely to further augment China as a leading market for Sulphur.

.

Sulfur Applications

Sulfur (sulfur granules and lump) has been known and applied from thousand years ago. It has a variety of uses in its different types as a sulfur powder (sulfur powder), sulfur pellets, granulated sulfur, and lump.

That is why sulfur consumption of a country was an index that implied its level of industrial activities.

One of its main and primary applications is to buy acid sulfuric production which itself is the raw material in producing organic chemicals, minerals, and mainly agricultural sulfur fertilizer.

Moreover, sulfur is used to produce explosive materials, rayon, reagents, color emollients, tires, matches, phosphate fertilizers, asphalt, sulfuric concrete, nitrogen fertilizers like ammonium sulfate and etc.

Sulfur Granules are also used as sulfur fertilizer (sulfur fertilizer) in agriculture. Hence Amoot Iranian Trading Company among chemical suppliers, as a major sulfur supplier is where to buy yellow sulfur powder, sulfur granules, and sulfur lumps.

We have sulfur for sale supplying from Turkmenistan and Uzbekistan sulfur manufacturers and sulfur fertilizer manufacturers. Hence if:

- you are thinking where to buy sulfur powder or where can I buy sulfur

- you are looking for sulphur powder suppliers

- you want to discover granular sulphur suppliers and granular sulphur price

.

Extensive Applications of Sulphur in Various Industries

Sulfur is known and discovered thousand years ago but it was mostly overlooked. Today, a huge area of focus is on sulfur as a practical and useful chemical in different industries. Its easy accessibility has made it an important raw material in industry and agriculture and consequently, it is well-paid attention to in recent decades. High activities in sulfur trading are originated from the wide scope of sulfur consumption in four main fields including agriculture, industry, pharmaceutical, and construction. The bellow diagram is representing various sulfur applications.

- Agriculture:

The importance of sulfur fertilizer in agriculture has been recognized for more than a century. Sulfur is one of the 17 essential plant nutrients. Although some agronomists believe that sulfur is the fourth major plant nutrient after nitrogen, phosphorus, and potassium which are critical components of a well-fertilized crop, many consider sulfur as the second most important nutrient, placed after nitrogen.

Due to the role of sulfur fertilizer in plant development, it is applied by farmers on large scale and globally. Some of the key effects of sulfur fertilizer on plants are as follow the formation of chlorophyll, protein, amino acids, vitamins, and enzymes as well as the synthesis of oils, and improvement of crop yields. Sulfur deficiencies can cause serious plant health problems and loss of vitality. This significance caused sulfur fertilizer to be a valuable product in the agro-industry.

- Industry:

Sulfur application in the industry is also wide and impressive. It is used to produce sulfuric acid, rubber, sugar, detergent, pigment, paper, plastic and etc. The main and primary use of sulfur is to produce sulfuric acid which is composed of sulfur, oxygen, and hydrogen. About 85~90% of the produced sulfur in the world is applied in sulfuric acid production. Sulfuric acid is a basic material used in the manufacturing of many final products.

- Pharmaceutical:

Sulfur is used in soap manufacturing. Along with the sulfur, are the ingredients used in making soap, such as mineral oil or vegetable oils, as well as lye, water, and fragrance. Most sulfur soap producers use a 10% sulfur content, although there are gentler versions with 3% content. Sulfur is also used in the production of some medicines.

- Construction:

Sulfur is even welcomed in the production of asphalt, concrete, floor covering, and house façade. Sulfur compounds are used in asphalt to reinforce and increase the resistance and durability of solvents of asphalt.

Amoot Iranian Trading Company as one of the professional leading chemical suppliers of Iran provides different kinds of sulfur including sulfur granules, prilled, crushed lumps, and sulfur powder for international clients.

We are here to facilitate the export process of sulfur fertilizer from Iran to any country worldwide and certify our customers that we are looking for long-term and reliable exporting of sulfur fertilizer.

Professional experts, high-quality sulfur fertilizer, and reasonable prices have all made Amoot Iranian Trading Company a promoted famous exporter of sulfur fertilizer.

.

Sulfuric Acid, the Main Product of Sulfur

Sulfuric acid (H2SO4) as the main product of sulfur is applied widely in various industries due to its acidity, reactivity, corrosive manner, sulfur content, and water solubility.

It is a material used to produce chemical fertilizers, paper, pulp, pigment, textile, detergent, plastic, battery, and explosive subjects. Also, sulfuric acid (alternative spelling sulphuric acid) is used in mineral processing, metal refining, water refinery, oil refining, and petrochemical processing.

About half of the global production of sulfuric acid is used to manufacture phosphoric acid, which is used largely in high-grade phosphate fertilizers. You can see the uses of sulfuric acid below the figure.

.

.

Sulfuric Acid Production

The main elements for sulfuric acid production are elemental sulfur or emission gas obtained from melting base metals and pyrite (iron sulfide). Elemental sulfur is burned or sulfide minerals are melted to produce sulfur dioxide (SO2).

This material becomes oxidized in presence of one more catalyst and creates sulfur trioxide (SO3).

Then sulfur trioxide changes to sulfuric acid by water absorption. Sulfuric acid can be made in various grades and densities. Bellow 4 stages of sulfuric acid production are mentioned:

- Extraction of sulfur

- Conversion of sulfur to sulfur dioxide

- Conversion of sulfur dioxide to sulfur trioxide

- Conversion of sulfur trioxide to sulfuric acid

.

Sulfuric acid producers and consumers

The largest chemical market is related to sulfuric acid by 6,242 million MT of production and consumption, worth more than 20 million dollars.

China, the USA, India, Russia, and Morocco are the main producers of sulfuric acid in the world. The key exporters of sulfuric acid are South Korea, Japan, and Canada. America, Chile, Morocco, Australia, India are also known as great importers of sulfuric acid.

.

Iran’s high potential in sulfuric acid production

About 44 companies are producing sulfuric acid mainly for the internal market of Iran, a total capacity of 1.98 million MT. The sulfuric acid demand in the internal market of Iran is less than 800,000 MT which is fulfilled by internal production. It should be noted that about 60% of Iran’s capacity to produce sulfuric acid is inactive.

High international demands for sulfuric acid and Iran’s great potential for sulfuric acid production made the Iranian government encourage and support Iranian producers of sulfuric acid. Not too far the name of Iran will be found as key manufacture of sulfuric acid.

Due to the wide market of sulfuric acid, Amoot Iranian Trading Company provides sulfur as the main element for sulfuric acid production. We are ready to supply different shapes of sulfur according to the customers’ needs including granulated sulfur, lumps, prilled, and sulfur powder. A large scope of our customers is the sulfuric acid producers, looking for an international, reliable, and professional chemical supplier.