.

Jumbo bags, also known as bulk bags or FIBCs (Flexible Intermediate Bulk Containers), come in a variety of types to meet specific industry needs.

.

What Are Jumbo Bags?

Jumbo bags are commonly used for packaging large quantities of powdered and granulated products. They are an improved version of woven bags, capable of handling weights of up to 1500kg without breaking.

However, it’s important to consider the specific requirements of the product being packaged before selecting a jumbo bag.

Jumbo bags are popular for their ability to simplify storage and transportation of bulk goods. They are widely used in various industries, including:

- agriculture

- construction

- mining

- chemical

.

When choosing a jumbo bag, it’s crucial to understand the specific requirements of the product that needs to be packaged. Different types of jumbo bags have varying features, such as:

- conductivity

- ventilation

- safety certifications

.

For instance, food-grade jumbo bags are ideal for packing food products because they are made from materials that are safe for contact with food.

On the other hand, conductive jumbo bags are suitable for industries like electronics and mining, where there’s a risk of electrostatic discharge.

UN-certified bags are used for the transportation of dangerous goods and must comply with strict safety standards set by the United Nations.

In conclusion, jumbo bags are an essential packaging option for bulk products. They come in different types and sizes, each tailored to meet the specific needs of different industries and products.

Understanding the requirements of the product to be packed is crucial when selecting a jumbo bag, as it ensures that the product is packaged in a way that guarantees safety, durability, and proper handling.

.

Various Types of Jumbo Bags

Here are some of the most common types of jumbo bags classified in four main groups:

.

Types of Jumbo Bags

| Type of Jumbo Bag | Description |

| Type A (regular) | Made from non-conductive materials, for use with non-flammable, non-explosive products. |

| Type B (Anti-static) | Jumbo bags of Type B, similar to Type A, don’t possess any protective measures against static electricity buildup. However, the material used in Type B has a lower voltage limit of less than 6 kV. These FIBCs are suitable for packing dry, flammable products but require a non-flammable environment without any combustible gases. |

| Type C (Conductive) | Jumbo bags of Type C are made of conductive fabric achieved through knitting multiple conductive threads. These threads are joined together and connected to a grounding point, requiring the bag to be grounded at all times. This type of FIBC is used for packing flammable materials and in environments where combustible gases are present. |

| Type D (Dissipative) | Jumbo Bag Type D is made of anti-static fabric with permanent discharge properties, which doesn’t require earthing but requires a grounded environment. |

.

Jumbo Bags Lifting Belts/Loops

Lifting loops or belts of jumbo bags are used for lifting jumbo bags.

There are 6 common types of lifting loops in jumbo bags.

- Cross corner loops

- Side seam loops

- Sleeve lifting or tunnel loops

- Hood lifting loops

- Ancillary loops

- Double stevedore straps

The table below explains each of them with images.

.

Jumbo Bags Lifting Loops

| No. | Types | Explanations | Images |

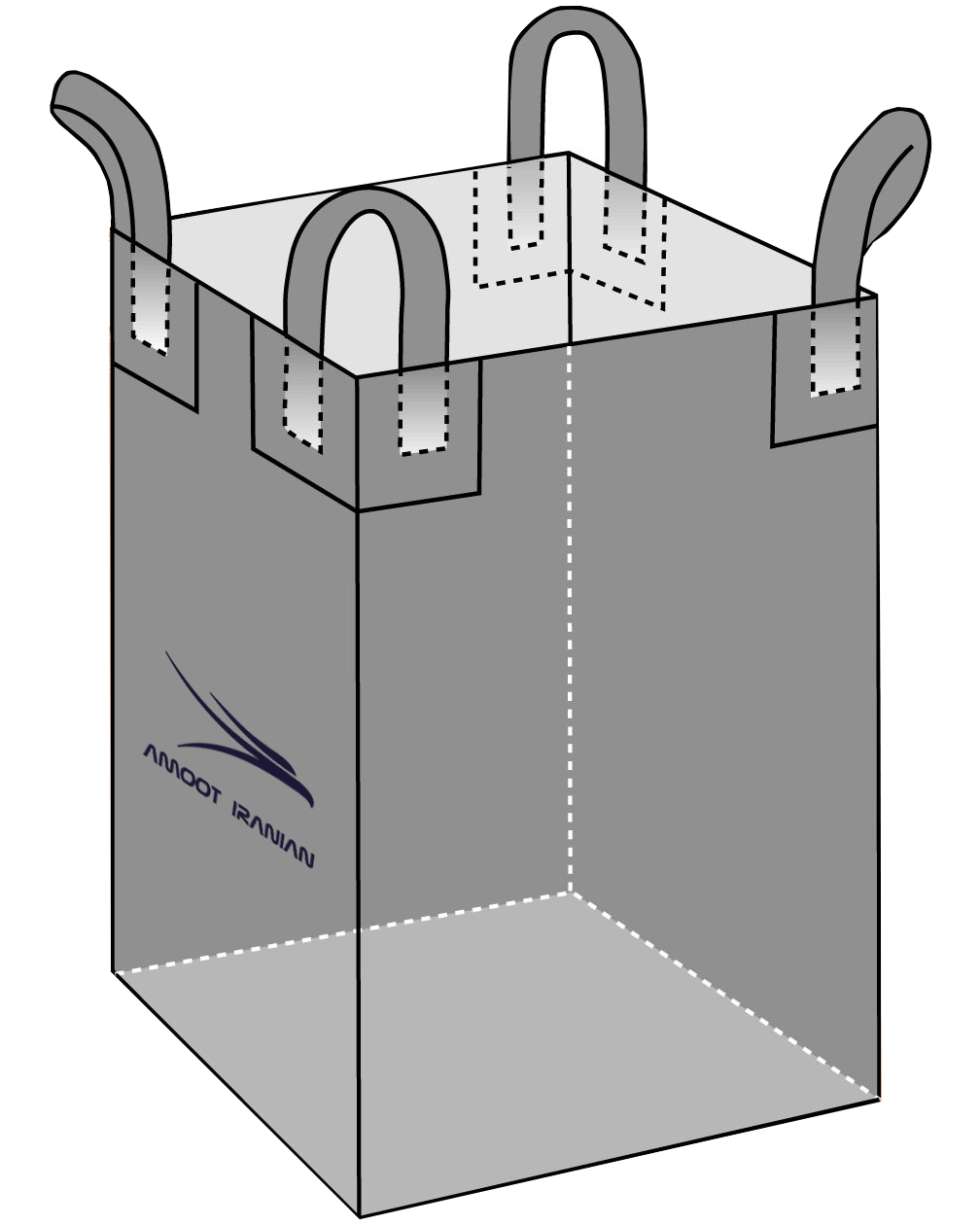

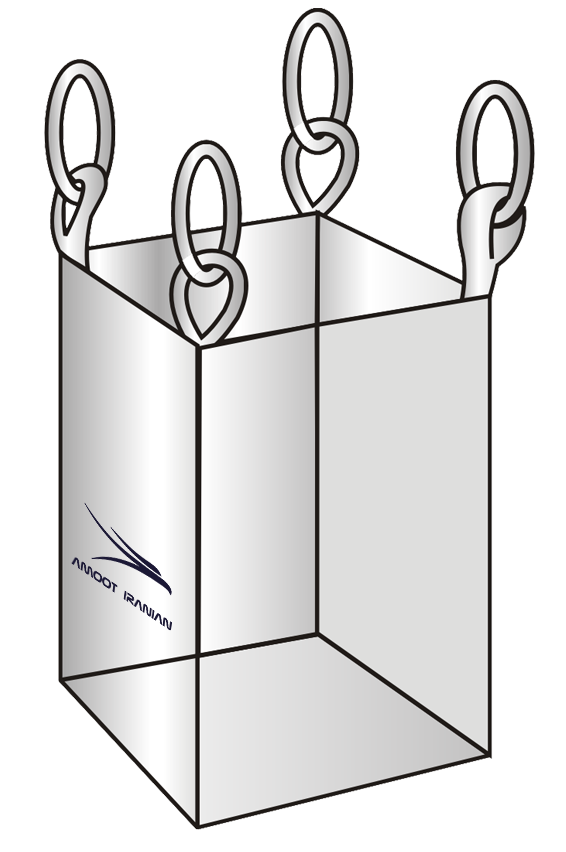

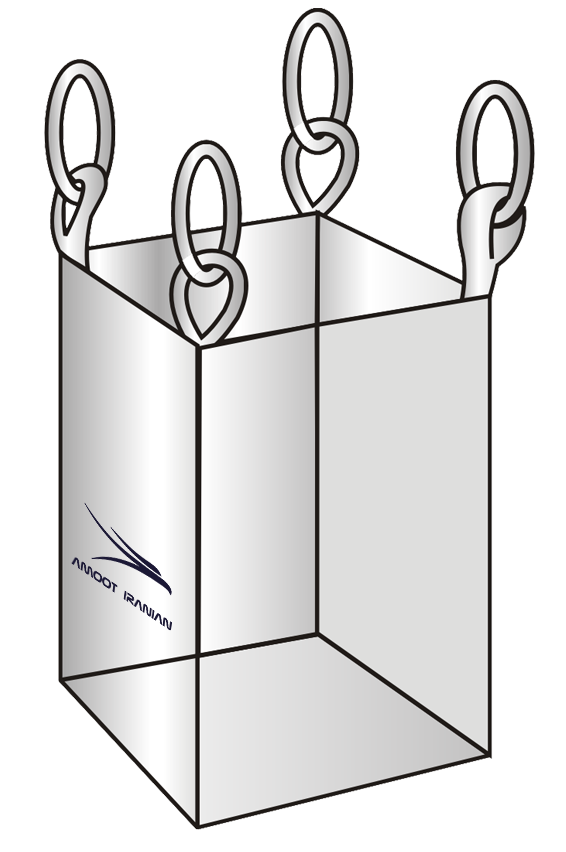

| 1 | Cross corner belts | They are attached to the body of the FIBC and create an arched shape over each corner. |  |

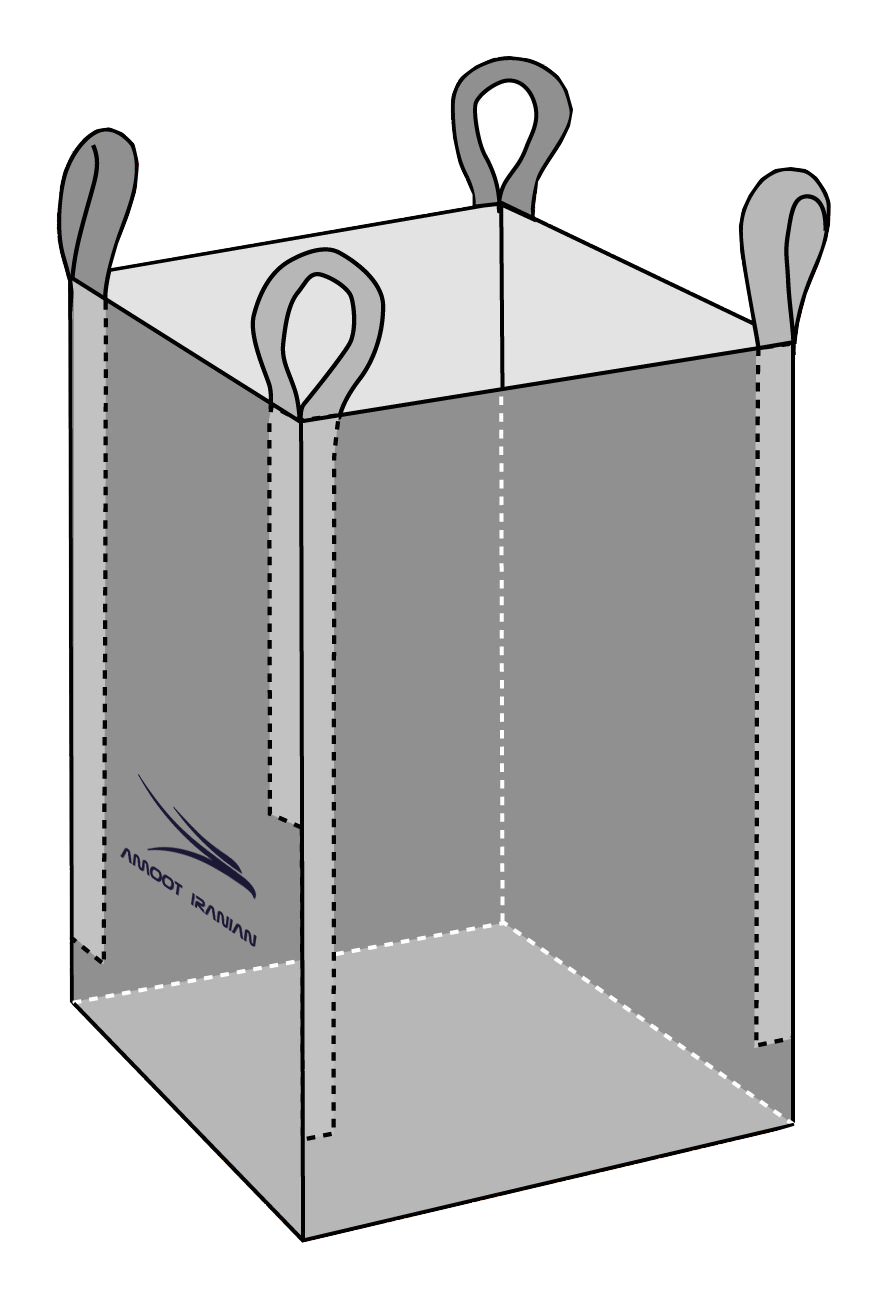

| 2 | Side seam loops | They are attached to the bag’s side seams, starting and ending at the same point on the bag, creating a tear-drop shape. |  |

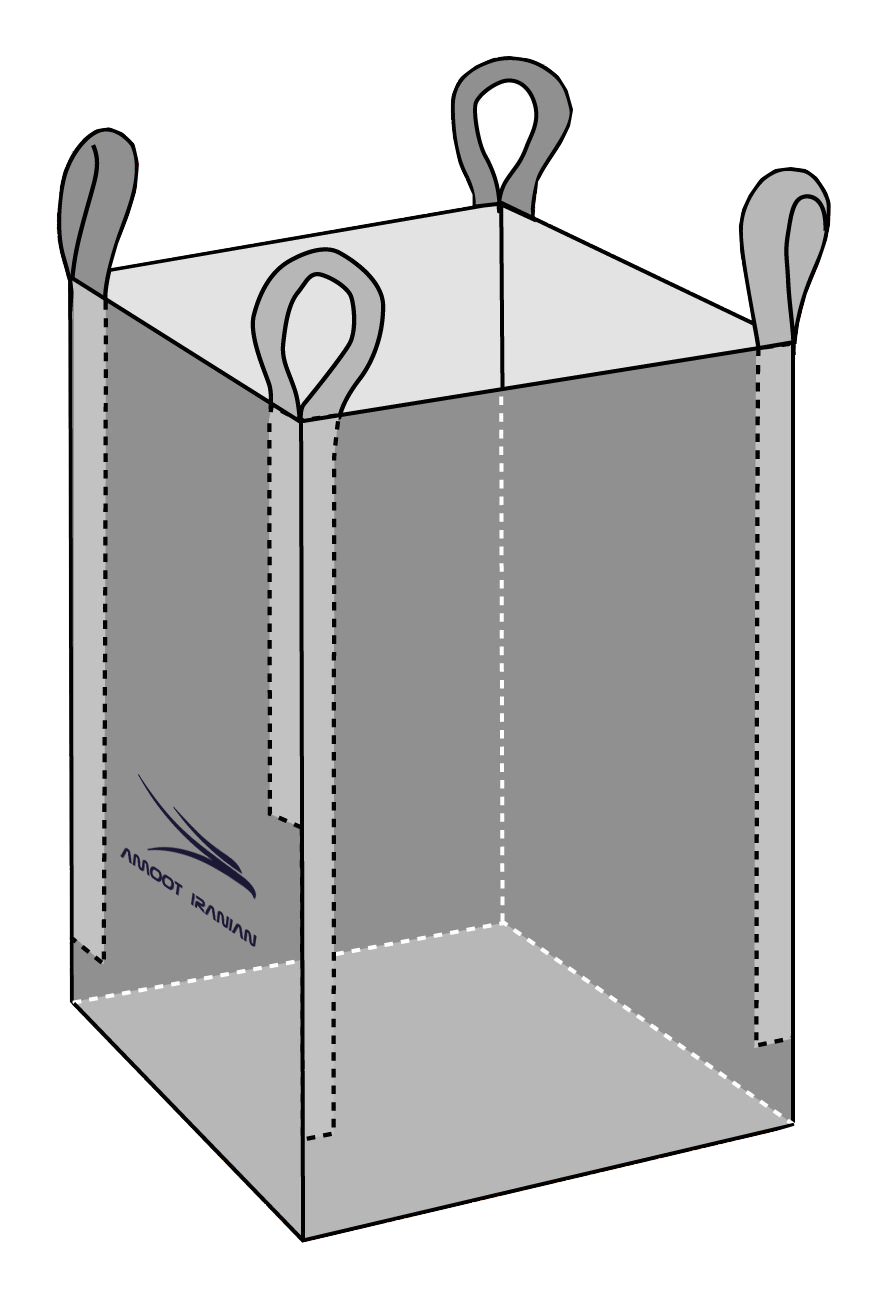

| 3 | Sleeve lifting loops/ Tunnel loops | These loops can be sewn into the top or bottom of the FIBC, providing exceptional stability while lifting and transporting. However, they may restrict forklift access to the bag. |  |

| 4 | Hood lifting loops | A hood lifting loop jumbo bag is a type of FIBC that has a hood at the top, which provides an additional lifting point. |  |

| 5 | Ancillary loops | Ancillary loops jumbo bag is a type of FIBC that has additional loops sewn onto the bag’s sides, providing extra support during lifting and transportation. |  |

| 6 | Double stevedore straps | In a double stevedore setup, two longer straps are looped through two of the straps sewn into the bag. |  |

.

Jumbo Bag Filling Head Sections

If you plan to use FIBC bags for your product, it’s crucial to determine which type of bag best suits your needs.

One of the key factors to consider is how you will fill and empty the bag. Several options are available for filling the bag, and specialized equipment is designed for this purpose.

It’s essential to select a bag that is compatible with your preferred or required methods for filling and emptying the bags such as:

- Open top

- Duffle top

- Spout top

.

Jumbo Bag Filling Head Sections

| No. | Types | Explanations | Images |

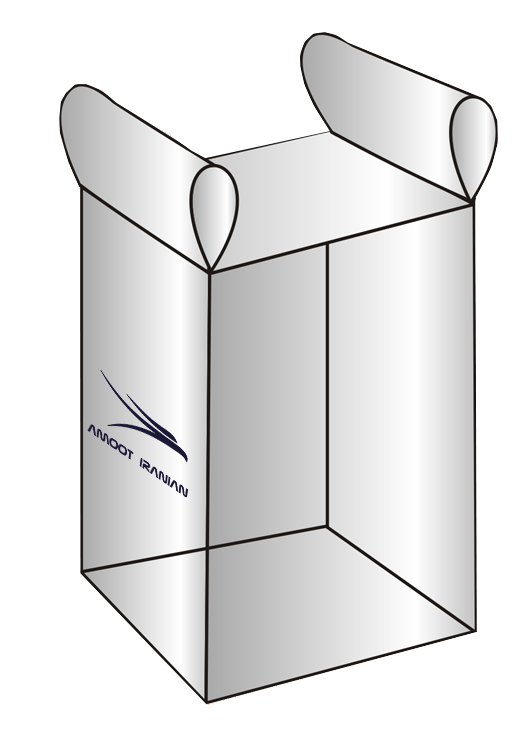

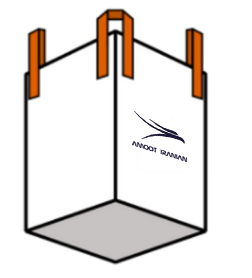

| 1 | Open top | The top of these jumbo bags are fully open. It is not possible to close these bags at all. |  |

| 2 | Duffle top | It includes a light weight panel on the top, with the same width and depth as the four sides of the bag. Essentially, it functions as a bag with a lid. If you require more flexibility for filling and emptying your bags, it may be a good option as its larger opening provides more choices. |  |

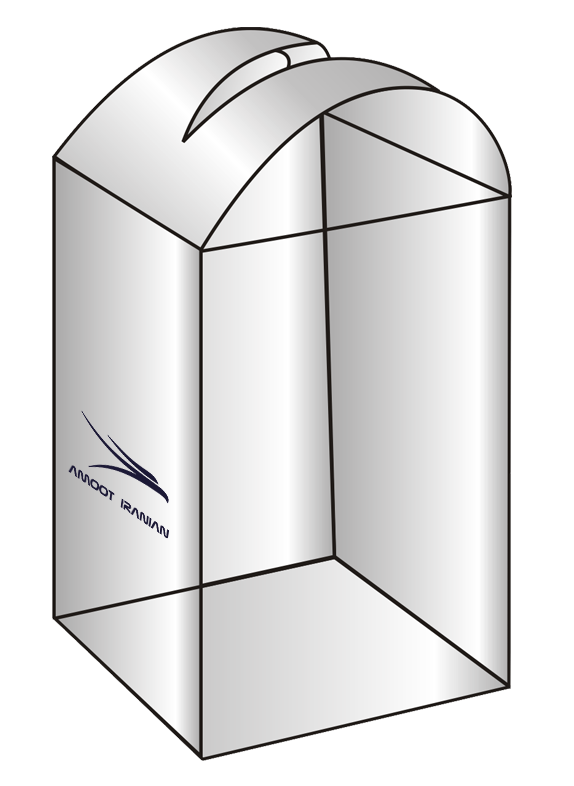

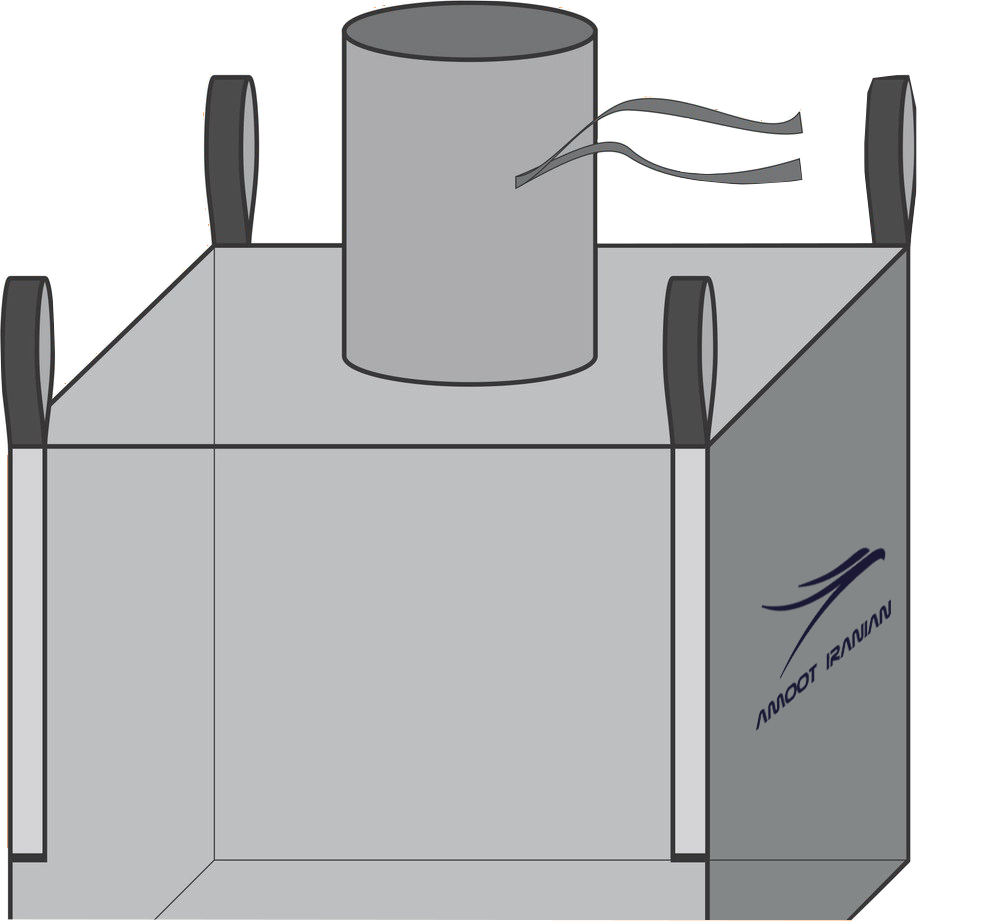

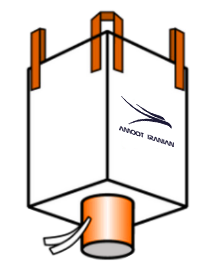

| 3 | Spout Top | It is designed with a spout sewn to the top panel of the bag, which is cylindrical and not as wide or deep as the rest of the bag. It provides a controlled method for filling and discharging the bag and is ideal for products that need to be filled quickly or with a high degree of accuracy. |  |

Jumbo Bag Discharge Spout

Discharge spout are used to discharge the product.

- Plain/flat/closed bottom

- Duffle bottom

- Discharge spout

- Discharge spout with cover

- Discharge spout with flap

- Conical discharge spout

- Iris closure

.

Jumbo Bag Discharge Spout

| No. | Types | Explanations | Images |

| 1 | Plain/flat/closed bottom | They have no spout and a closed bottom. They are good for single-use applications. The product must be cut from the bottom to be emptied. |  |

| 2 | Duffle bottom | It is for easy and quick discharge of bulk materials, particularly those that do not flow easily or may clump together over time. |  |

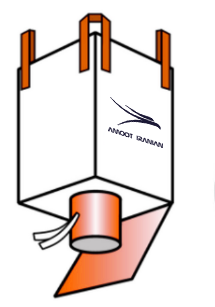

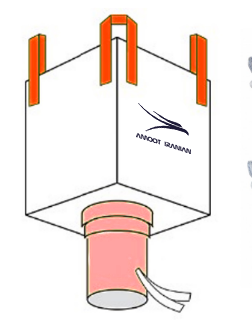

| 3 | Discharge spout | It is a commonly used feature that allows for controlled and precise discharge of bulk materials. The spout is located at the bottom of the bag and remains closed until it is time to unload the contents. This design allows for easy and controlled discharge without damaging the bag or losing any of the material. |  |

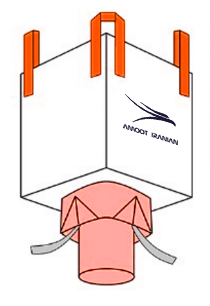

| 4 | Discharge spout with cover | The discharge spout is the opening at the bottom of the bag that allows the contents to be emptied out. To cover and protect the discharge spout, a petal or star closure is sewn from heavy fabric. These closures are designed to fit tightly over the spout and prevent any material from leaking out during transport or storage. |  |

| 5 | Discharge spout with flap | A discharge spout with a flap, also known as a sanitary flap, is a type of closure commonly used in industries where hygiene and cleanliness are of utmost importance, such as in the food or pharmaceutical industries. This closure is designed to protect the entire bottom surface of the bag from contamination. |  |

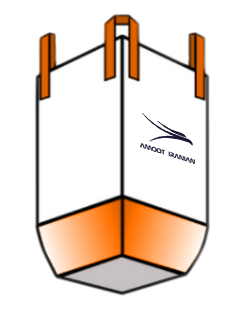

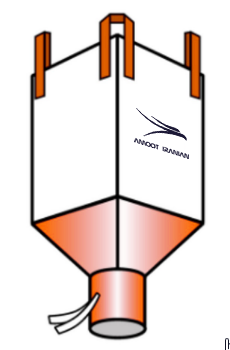

| 6 | Conical discharge spout | The spout is sewn into the bottom of the bag in a conical shape, allowing for the entire bag to be emptied of its contents. One common issue with standard FIBCs is that material tends to accumulate in the corners of the bag, making it difficult to fully empty the bag. However, with a conical discharge spout, this issue is minimized as the shape of the spout allows for easier flow of the contents out of the bag. |  |

| 7 | Iris closure | An iris closure is a type of closure used in bulk bags or FIBCs (Flexible Intermediate Bulk Containers) to control the flow of materials being discharged from the bag’s bottom spout. This closure is ideal when a fixed connection is not necessary, as it allows for more flexibility in controlling the flow of materials. |  |

Amoot Iranian Trading Company provides 1 MT quality jumbo bags for transport of sulfur, the pictures of which can be seen below.

Most of the sulfur’s jumbo bags of Amoot have open or spout top and closed bottom, which explained before.

.

Oh, very useful, especially the images you added to the tables.

Complete and clear …