.

What Is Iron Ore?

Iron ore is a mineral substance that has iron in adequate amounts to be commercially worthwhile for extraction.

.

The primary sources of iron ore are rocks and minerals known as iron oxides, which include:

.

.

Iron Ore Uses

Iron ore is an essential raw material used in the production of steel. Steel is one of the most widely used construction materials in the world.

.

The iron in iron ore is extracted through a process known as smelting, which involves heating the ore to very high temperatures and separating the iron from other minerals and impurities.

“To get to the bits of iron in the ore, you have to smelt it out. Smelting involves heating up ore until the metal becomes spongy and the chemical compounds in the ore begin to break down. Most important, it releases oxygen from the iron ore, which makes up a high percentage of common iron ores.” (howstuffworks)

The extracted iron is then purified and used to make a wide range of products, including structural steel, automobiles, machinery, and appliances.

Iron ore is found in many countries around the world, with the largest deposits located in Australia, Brazil, China, India, Russia, and Ukraine.

.

Seven countries with the largest iron ore reserves in the world

.

.

What Are The Steps Of Mining Iron?

.

Iron ore mining process

.

1. Exploration

Iron ore deposits are first identified by prospecting teams that use geological data, satellite imagery, and other tools to locate potential sites.

.

2. Planning

Once a promising site is identified, mining engineers assess the site’s feasibility and develop a plan for mining.

.

3. Extraction

The first step in the extraction process is drilling and blasting to break up the ore and loosen it from the surrounding rock. The ore is then excavated and transported to the processing plant.

.

4. Crushing and screening

The extracted ore is crushed into small pieces and screened to remove any impurities. The resulting product is called “lump ore,” which is used in the production of steel.

.

5. Grinding

The lump ore is further ground into fine particles in a process known as “grinding.” The resulting product is called “fines,” which is also used in the production of steel.

.

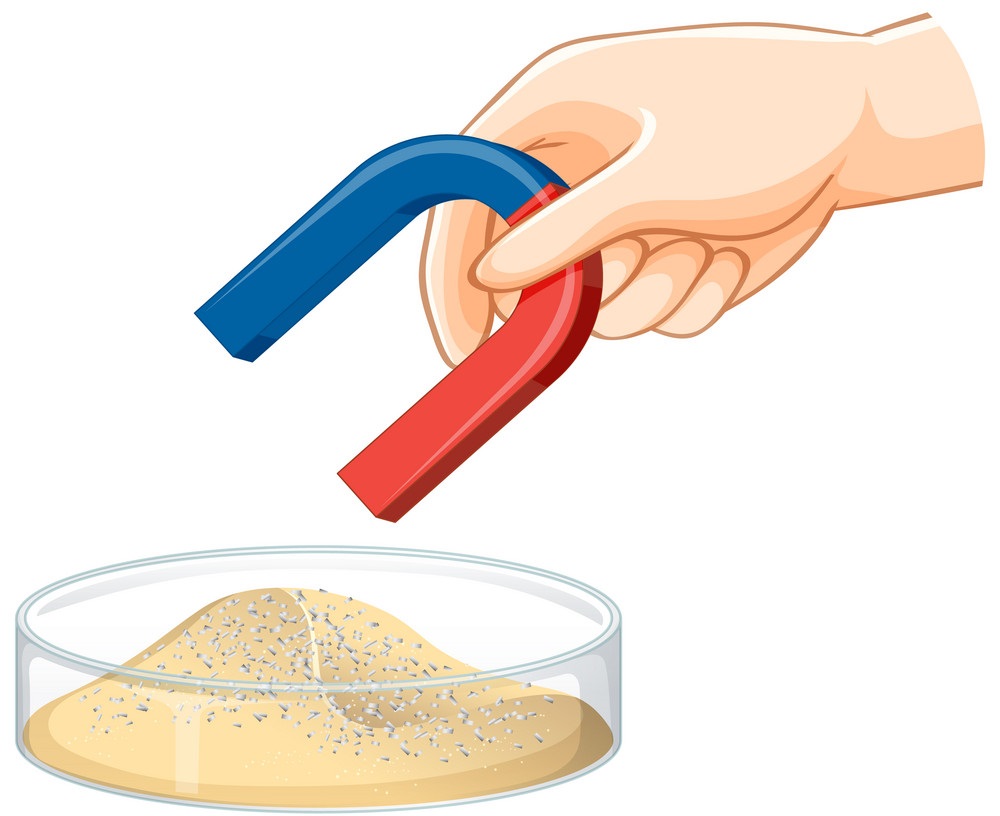

6. Magnetic separation

The fine particles of iron ore are then separated from the impurities using magnetic separators.

.

7. Pelletizing

The iron ore fines are agglomerated into pellets using a process known as “pelletizing.”

The pellets are then roasted in a furnace to make them hard and durable.

.

8. Shipping

The final product is shipped to steel mills, where it is used in the production of steel.

.

The mining process of iron ore can vary depending on the type of ore deposit and the mining technology used.

However, the above stages represent the general process followed in most iron ore mining operations.

.

.

Iron Ore Price

The price of iron ore is affected by a range of factors, including:

.

1. Supply and demand

The most significant factor affecting the price of iron ore is the balance of supply and demand in the global market.

When demand for iron ore is high and the supply is low, prices will rise. Conversely, when supply exceeds demand, prices will fall.

.

2. Production costs

The cost of mining, processing, and transporting iron ore also impacts its price. Higher production costs, such as labor, energy, and equipment costs, can lead to higher iron ore prices.

.

3. Exchange rates

The exchange rate between the currency used to trade iron ore and other currencies can also affect the price.

For example, if the currency used to trade iron ore strengthens against other currencies, the price of iron ore may rise.

.

4. Economic conditions

Economic conditions in major iron ore-consuming countries can also affect the price of iron ore.

If the global economy is growing and demand for steel is high, prices may rise. Conversely, if economic growth slows down, prices may fall.

.

5. Government policies

Government policies, such as taxes, tariffs, and export restrictions, can also impact iron ore prices.

For example, if a country imposes high export tariffs on iron ore, prices may rise in the global market.

.

Overall, the price of iron ore is influenced by a range of factors, making it a complex and dynamic market.

.

.

Amoot: Your One-Stop Shop for Pure Iron Ore!

Amoot Iranian Trading Company is an old and reliable iron ore producer and exporter based in Iran.

With various mines located in the east of Iran, Amoot supplies high-quality, pure iron ore at competitive prices.

We use the most modern facilities and techniques to mine our iron ore, ensuring that it meets the strictest quality standards.

.

.

As a manufacturer and exporter of iron ore, we are committed to providing our customers with the best possible products and services.

We work closely with our clients to understand their needs and deliver customized solutions that meet their specific requirements.

Whether you’re a steel mill looking for a consistent supply of high-quality iron ore, or a trading company searching for a reliable partner, Amoot is here to help.

.

Contact us today to learn more about our products and services and how we can help you succeed in the global marketplace.