.

.

Simply put, slow-release urea (SRU) is a type of fertilizer that is made to release nitrogen into the soil at a slower rate than traditional urea fertilizers.

.

Nitrogen is an indispensable nutrient for plant growing, but it is simply leached from the soil.

It can result in waste and environmental pollution.

.

.

What Is Slow Release Fertilizer?

As a rule of thumb, slow-release fertilizer is a kind of fertilizer that is designed to release nutrients into the soil at a slower and more controlled rate than old-style fertilizers.

.

This type of fertilizer is also known as:

- controlled-release fertilizer

- timed-release fertilizer

.

Slow-release fertilizers are made by coating the granules of old fertilizers with a material that breaks down gradually over time, releasing the nutrients into the soil slowly.

The coating can be made from a variety of materials, such as sulfur, polymers, or resins.

.

.

The Benefits Of Slow-Release Fertilizers

.

1. Improved efficiency

Slow-release fertilizers can reduce the amount of fertilizer needed, as they release nutrients over a longer period of time.

It reduces the risk of nutrient loss through leaching or runoff.

.

2. Reduced environmental impact

By releasing nutrients gradually, slow-release fertilizers can reduce the environmental effect of fertilizer runoff, which can contribute to water pollution.

.

3. Long-lasting effects

Slow-release fertilizers can provide nutrients to plants over a longer period, minimizing the need for frequent applications and providing sustained growth and health for plants.

Slow-release fertilizers are commonly used in agriculture, horticulture, and landscaping, and are suitable for a wide range of crops.

..

What Is Slow Release Urea?

As mentioned before, slow-release urea (SRU) is a type of fertilizer that is designed to release nitrogen into the soil at a slower rate than traditional urea fertilizers.

.

.

Nitrogen is an essential nutrient for plant growth, but it is easily leached from the soil, which can result in waste and environmental pollution.

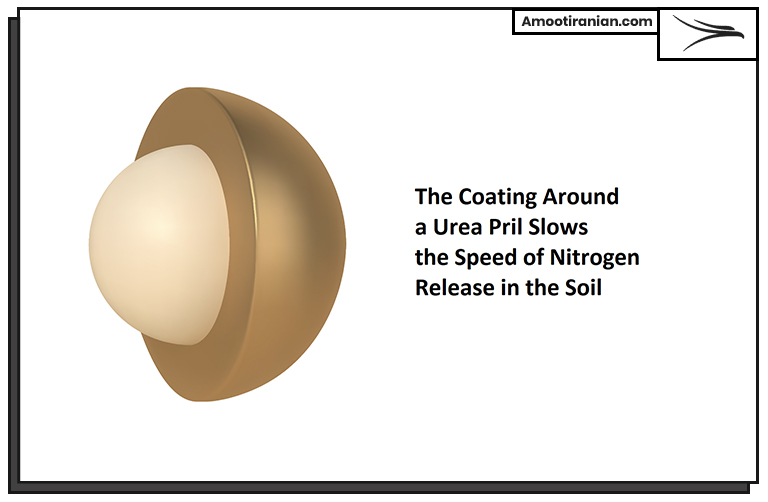

SRU works by coating the urea granules with a material that slows down the release of nitrogen.

The coating can be made from a variety of materials, such as sulfur, polymers, or resins, which gradually break down over time and release nitrogen into the soil.

This slow-release process ensures that the nitrogen is available to the plants over a longer period, reducing the risk of leaching and increasing efficiency.

SRU is particularly useful for crops that require a continuous supply of nitrogen over a long growing season, such as corn, wheat, and rice.

It is also beneficial for reducing the amount of fertilizer needed, as well as minimizing the impact of nitrogen runoff on the environment.

.

Is Traditional Urea A Slow-Release Fertilizer?

Urea is not a slow-release fertilizer in its pure form. It is a quick-release fertilizer, which means that it rapidly dissolves in soil water, and the nitrogen it contains becomes available to plants immediately.

.

However, manufacturers can treat urea with various coating materials to create slow-release urea (SRU), which releases nitrogen into the soil gradually over an extended period.

The coating material can be made from polymers, resins, or sulfur, and it is designed to break down slowly, allowing the nitrogen to release slowly into the soil.

SRU works by coating the urea granules with a material that slows down the release of nitrogen.

.

The coating can be made from a variety of materials, such as sulfur, polymers, or resins, which gradually break down over time and release nitrogen into the soil.

This slow-release process ensures that the nitrogen is available to the plants over a longer period, reducing the risk of leaching and increasing efficiency.

SRU is particularly useful for crops that require a continuous supply of nitrogen over a long growing season, such as corn, wheat, and rice.

It is also beneficial for reducing the amount of fertilizer needed, as well as minimizing the impact of nitrogen runoff on the environment.

.

.

How Do You Make Slow Release Urea?

There are different methods for making slow-release urea (SRU), but a common approach involves coating the urea granules with a material that gradually releases nitrogen into the soil.

Here are the general steps for making SRU:

.

1. Choose a coating material

There are various coating materials that can be used to slow down the release of nitrogen from urea, such as sulfur, polymers, or resins.

The choice of coating material depends on factors such as the desired release rate, the cost, and the environmental impact.

.

2. Prepare the coating solution

The coating material is typically dissolved or suspended in water or a solvent to make a coating solution.

Other additives, such as surfactants or adhesion agents, may be added to improve the coating properties.

.

3. Apply the coating solution

The urea granules are then coated with the coating solution using a coating drum or other equipment.

The coating thickness and uniformity can be controlled by adjusting the coating solution concentration and the coating process parameters.

.

4. Dry and cure the coated urea

After the coating application, the coated urea is usually dried and cured to remove excess moisture and to allow the coating material to harden and adhere to the urea granules.

This step may require specialized drying equipment and may take several hours or days.

.

The exact process for making slow-release urea can vary depending on the specific coating material and formulation used.

It is important to optimize the coating process to ensure that the coated urea has the desired release properties and does not affect the handling and storage of the fertilizer.

.

Is Slow-Release Urea More Expensive Than Traditional Urea?

Is It Affordable to Use It Instead of Old Urea?

Slow-release urea is usually more expensive than old-style urea because of the additional cost involved in coating the urea granules with a material that gradually releases nitrogen into the soil.

The coating material, equipment, and labor required to make SRU can all add to the cost.

However, the cost of using SRU instead of traditional urea may vary depending on factors such as the crop type, soil conditions, and climate.

.

For some crops, using SRU can be more cost-effective than traditional urea, as it can reduce the frequency of fertilizer applications, minimize the risk of nutrient loss, and increase crop yields.

In some cases, the benefits of SRU may outweigh the additional cost of the fertilizer.

.

Moreover, the cost of fertilizer is not the only factor to consider when choosing between SRU and traditional urea.

The environmental impact of nitrogen leaching and runoff can be significant, and the use of SRU can help reduce this impact.

Additionally, regulations and policies may influence the choice of fertilizer, as some regions may restrict the use of traditional urea due to environmental concerns.

.

Therefore, while SRU may be more expensive than traditional urea, it is worth considering its potential benefits in terms of crop productivity, environmental impact, and regulatory compliance.

.

Various Types of Slow Release Urea

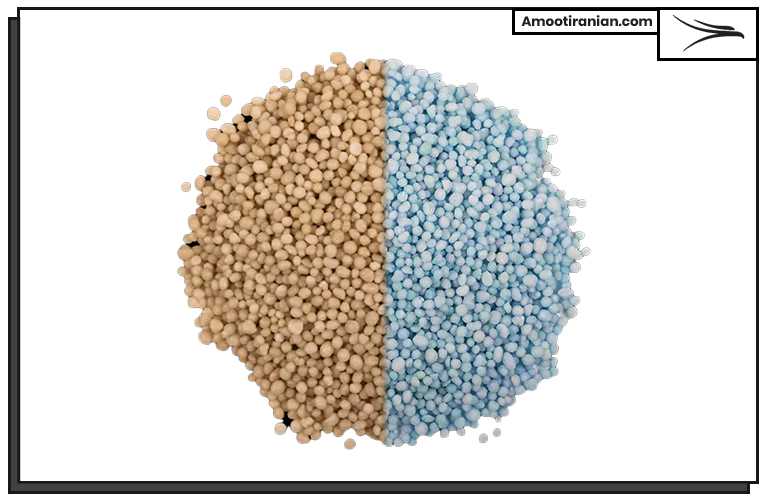

There are several types of slow-release urea (SRU) available in the market, and each type uses a different coating material and technology to release nitrogen gradually into the soil.

.

Here are some of the common types of SRU:

1. Polymer-coated urea

Polymer-coated urea uses a thin layer of polymer resin to coat the urea granules. The polymer coating gradually releases nitrogen through a process of diffusion, which can last for several weeks or months, depending on the polymer type and thickness.

.

2. Sulfur-coated urea

Sulfur-coated urea (SCU) uses a layer of elemental sulfur to coat the urea granules. The sulfur coating oxidizes in the soil, releasing nitrogen slowly over several weeks or months. SCU is particularly effective in acidic soils, as the sulfur coating can also help to lower the soil pH.

.

3. Urea formaldehyde (UF) and Urea-triazone

These are two types of slow-release fertilizers that use urea as the nitrogen source and formaldehyde or triazone as the coating material. The coating gradually decomposes in the soil, releasing nitrogen over several months. UF and Urea-triazone can be particularly useful for crops that require a continuous supply of nitrogen over an extended period.

.

4. Nutrient stabilized urea (NSU)

NSU is a type of SRU that combines urea with a stabilizing agent, such as nitrification or urease inhibitors, to prevent nitrogen loss through leaching or volatilization. The stabilizing agent can help to prolong the release of nitrogen and make the fertilizer more efficient.

The choice of SRU type depends on several factors, including the crop type, soil conditions, climate, and cost. Each type of SRU has its advantages and disadvantages, and it is essential to choose the right type based on the specific needs of the crop and the soil.

.

Which Of The Slow Release Urea Fertilizers Is The Best Of All?

The best type of slow-release urea (SRU) depends on various factors, including:

- soil conditions

- climate

- crop type

- fertilizer management practices

.

Here are some factors to consider when choosing the best type of SRU:

1. Release rate

The release rate of nitrogen from SRU can vary depending on the coating material and technology used. Some types of SRU release nitrogen quickly, while others release nitrogen slowly over an extended period.

The choice of SRU should be based on the crop’s nitrogen requirement and the desired release rate.

.

2. Soil conditions

Soil pH, texture, and organic matter content can affect the performance of SRU. For example, sulfur-coated urea (SCU) is more effective in acidic soils, while polymer-coated urea is more suitable for alkaline soils. It is essential to choose the type of SRU that matches the soil conditions and the crop’s nutrient needs.

.

3. Climate

Temperature and rainfall can influence the release rate and efficiency of SRU. For example, UF and Urea-triazone may not perform well in cold climates, while NSU can be effective in areas with high rainfall.

.

4.Crop type

Different crops have different nutrient requirements, and the choice of SRU should be based on the crop’s specific needs. For example, SCU may not be suitable for crops that require a rapid release of nitrogen, such as corn or rice.

.

5.Cost

The cost of SRU can vary depending on the coating material, technology, and region. It is essential to choose the type of SRU that provides the best value for money based on the crop’s yield potential, fertilizer management practices, and environmental impact.

.

In summary, the choice of the best type of SRU depends on several factors, and it is important to evaluate these factors and choose the most appropriate type of SRU for the specific crop and soil conditions.

.

Consultation with a local agronomist or fertilizer expert can also be helpful in making the right choice.