.

Urea production involves several steps, including the synthesis of ammonia and carbon dioxide, separation and purification of the ammonia, reaction with carbon dioxide to form urea, prilling, drying, coating (optional), and bagging and storage.

.

.

Urea Market

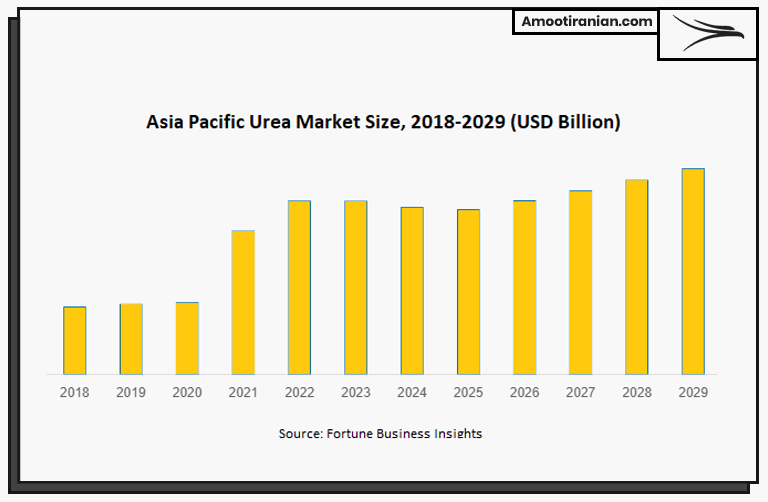

Before explaining urea production steps in detail, let’s investigate the urea market briefly.

Over the past years, the global urea market has experienced significant growth and has reached a volume of around 180 million tonnes in 2022.

It is projected to continue growing at a consistent compound annual growth rate of 4.10% until 2032.

.

The forecast of Fortune Business Insights.

.

The global market for urea is expected to increase from $129.52 billion in 2022 to $150.61 billion by 2029.

This represents a projected annual growth rate of 2.2% during the forecast period of 2022-2029.

.

.

Urea Production Steps

Here’s a table summarizing the complete procedure of urea production:

.

Urea Production Steps

| Step | Description |

| Synthesis | Ammonia and carbon dioxide are reacted in a reactor vessel under high temperature and pressure using the Haber-Bosch process. |

| Stripping | The ammonia gas is separated from unreacted carbon dioxide, water, and other impurities using a stripping tower. |

| Scrubbing | The ammonia gas is washed and scrubbed with water to remove any remaining impurities. |

| Carbon Dioxide Recovery | The carbon dioxide is recovered from the remaining gas mixture and recycled back into the reactor vessel. |

| Urea Synthesis | The purified ammonia is mixed with carbon dioxide in a reactor vessel and allowed to react to form urea using the Stamicarbon process. |

| Prilling | The urea solution is sent to a prilling tower where it is sprayed with a fine mist of water to form small solid particles. |

| Drying | The urea particles are dried in a fluidized bed dryer. |

| Coating | Urea particles may be coated with a material to improve their flowability and reduce caking. |

| Bagging and Storage | The final step is the bagging and storage of the urea for shipment and use. |

.

How Many Type of Urea Fertilizer Do We Have?

There are two main types of urea fertilizer:

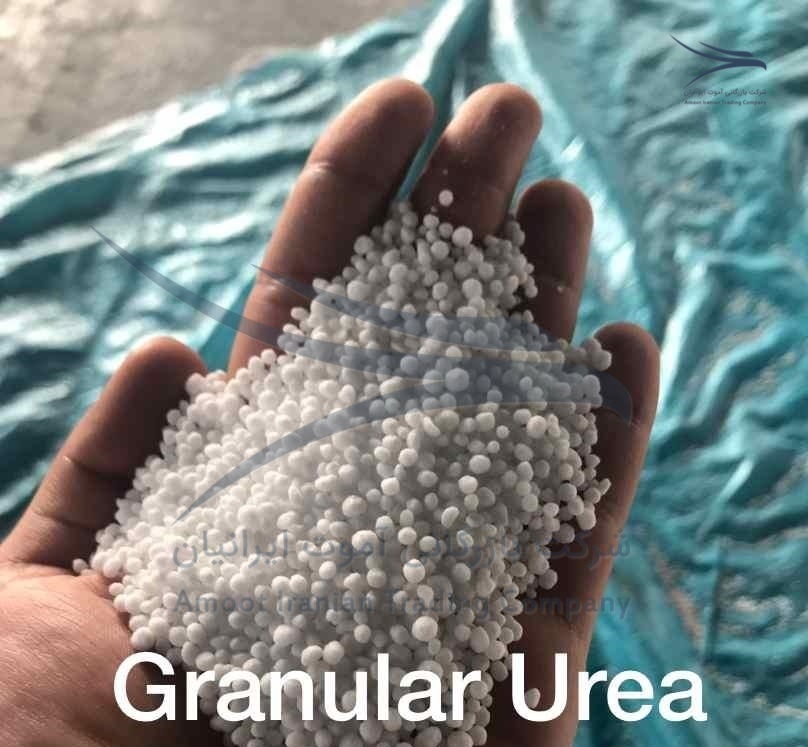

- Granular urea

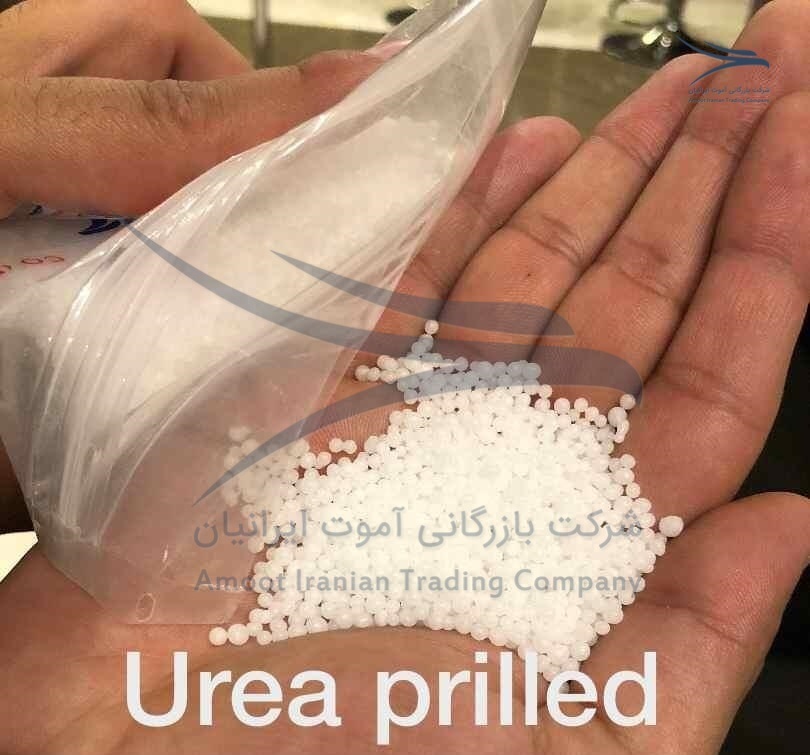

- Prilled urea

.

| Granular Urea | made by spraying a urea solution onto a bed of recycled granules, which grow larger as the urea solution is added |

| Prilled Urea | made by spraying droplets of urea solution into a tower, which then solidify into small spherical pellets or prills |

.

Urea Production Plant

An Urea Production Plant, also known as a urea factory, is a large industrial facility that specializes in the production of urea fertilizer.

The process involves several steps, including the reaction of ammonia and carbon dioxide to form ammonium carbamate, which is then dehydrated to form urea.

The urea solution is then concentrated through evaporation or crystallization and can be further processed into prills or granules.

Urea factories require specialized equipment and infrastructure to handle the raw materials and products at each stage of the process. T

The production process involves high-pressure reactions and high-temperature processing, which require robust equipment and safety protocols to ensure the safety of workers and the environment.

.

.

The raw materials required for the production process include ammonia and carbon dioxide, which are typically obtained from fossil fuel sources such as natural gas.

The production of urea can be energy-intensive, and the use of fossil fuels can result in significant greenhouse gas emissions.

As a result, there has been increasing interest in developing more sustainable and environmentally friendly processes for producing urea, such as incorporating renewable energy sources and carbon capture and utilization technologies.

Overall, urea factories play a critical role in the production of urea fertilizer, which is an essential input for agriculture and is used around the world to promote crop growth and food security.

.

Urea Production by Country

Who is the biggest manufacturer of urea?

What country is the largest producer of urea? What countries supply urea?

The list of top urea producing countries are demonstrated below from 2017 to 2019, as mentioned in Nation Master.

.

3 Top Countries in Urea Fertilizer Production (Million Metric Tons) – 2017 to 2020

| Ranking | Country | Urea Production in 2017 in Million Tons | Urea Production in 2018 in Million Tons | Urea Production in 2019 in Million Tons | Urea Production in 2020 in Million Tons |

| 1 | India | 24.02 | 23.89 | 24.28 | 24.6 |

| 2 | Russia | 8.00 | 7.96 | 8.17 | 8.79 |

| 3 | Indonesia | 6.83 | 7.44 | 7.33 | 7.98 |

.

Does Iran produce urea?

Iran is one of the major producers of urea in the world. The country has several urea production plants, including the Shiraz Petrochemical Complex, the Marun Petrochemical Complex, and the Masjed Soleiman Petrochemical Complex, among others.

Iran exports a significant amount of its urea production to various countries around the world, including India, Brazil, and several countries in Southeast Asia.

.

Amoot’s Urea

Amoot Iranian Trading Company is a large and leading exporter of Iran’s urea fertilizer to any destination at any part of the globe.

.

.

However, Turkmenistan’s urea is also supplied by Amoot Company.

Amoot Iranian Trading Company has established itself as a trusted and reliable supplier of urea fertilizer, with a focus on meeting the needs of its customers around the world.

The company has a wide network of contacts in the urea industry, and it works closely with producers in Iran and Turkmenistan to ensure that its customers receive high-quality products at competitive prices.

.

.

In addition to exporting urea fertilizer, Amoot also provides logistics and transportation services to ensure that the product reaches its destination on time and in good condition.

With its expertise and experience in the urea industry, Amoot Iranian Trading Company is well-positioned to meet the growing demand for this important agricultural input.