.

.

.

Some Differences Between Lump And Granular Sulfur

| Property | Lump Sulfur | Granular Sulfur |

Physical Form | Large solid pieces | Small granules |

Appearance | Yellowish-brown or orange | Yellowish-brown or grayish |

Purity | Typically high | Typically high |

Handling | Can be difficult to handle | Easy to handle |

Application | Industrial use | Agricultural use |

Melting Point | High (approx. 115°C) | Lower (approx. 107°C) |

Solubility | Insoluble in water | Insoluble in water |

Rate of Release | Slow | Fast |

Cost | Cheaper | More expensive |

.

Physical Form

Lump sulfur is a solid form of sulfur that typically comes in large pieces, which can range from a few centimeters to several inches in size. These pieces can be irregular in shape and have a rough surface texture.

.

.

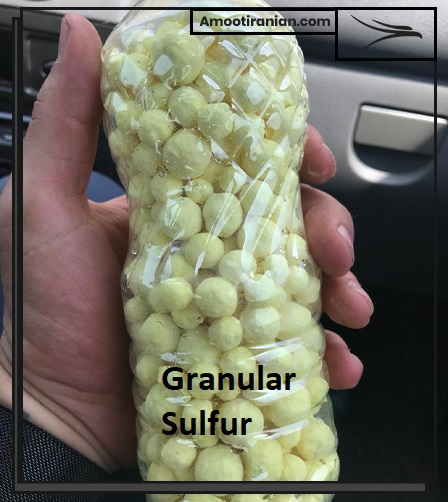

Granular sulfur is a more finely divided form of sulfur that is made up of small, uniform-sized granules. These granules are typically around 1-5 mm in diameter and have a smooth surface texture.

.

.

Appearance

Lump sulfur typically has a yellowish-brown or orange color and can have a rough, irregular surface texture. The color may vary slightly depending on impurities or other factors, but it is generally a shade of yellow or brown.

Granular sulfur also typically has a yellowish-brown color, although it may sometimes appear grayish. The granules are usually smooth and uniform in size and shape.

.

It’s worth noting that the color and appearance of sulfur can be affected by a variety of factors, such as impurities, processing methods, and storage conditions.

For example, sulfur that has been stored in the presence of moisture or air may develop a powdery surface coating or turn yellow over time.

.

Purity

Both lump sulfur and granular sulfur can be highly pure, depending on the specific production process and grade of sulfur being used.

In general, sulfur with a high degree of purity is desirable for many industrial and agricultural applications because impurities can negatively affect the properties and performance of the sulfur.

.

.

Application

For industrial applications, such as the production of sulfuric acid or other chemicals, high-purity lump sulfur is often preferred because it can be easier to handle and process in bulk quantities.

For agricultural applications, such as soil amendment, granular sulfur is often preferred because it can be more easily applied and incorporated into the soil.

.

Regardless of the physical form, sulfur can be produced with high purity through various refining and processing techniques, such as distillation, sublimation, and filtration.

Therefore, the purity of sulfur is not necessarily determined by its physical form, but rather by the specific production methods and quality control measures used.

.

Melting Point and Solubility

.

The melting point and solubility of sulfur can vary depending on its physical form and other factors. Here are some general observations:

.

Melting point

- Lump sulfur generally has a higher melting point than granular sulfur. The melting point of lump sulfur is around 115°C (239°F).

- Granular sulfur, on the other hand, has a lower melting point than lump sulfur. The melting point of granular sulfur is around 107°C (225°F).

.

Solubility

- Both lump sulfur and granular sulfur are insoluble in water.

- However, sulfur can dissolve in certain organic solvents, such as carbon disulfide, benzene, and toluene.

- The solubility of sulfur in these solvents can depend on factors such as temperature and pressure, as well as the specific type and grade of sulfur being used.

.

It’s important to note that the sulfur melting point and solubility can be influenced by various factors, such as the purity, particle size, and crystal structure of the sulfur.

Therefore, the specific melting point and solubility of sulfur can vary depending on the specific type and grade of sulfur being used.

.

.

Rate of Release

The rate of release of sulfur can depend on its physical form and other factors, such as soil conditions and environmental factors. Here are some general observations:

.

Granular sulfur

- Granular sulfur typically releases sulfur relatively quickly after application.

- The release rate can depend on various factors, such as soil temperature, moisture levels, and microbial activity.

- In general, granular sulfur is a fast-release form of sulfur, meaning that it can provide a relatively quick source of sulfur for plants.

/

Lump sulfur

- Lump sulfur is generally a slow-release form of sulfur.

- The release rate of sulfur from lump sulfur can depend on various factors, such as particle size and surface area, as well as soil conditions and microbial activity.

- Due to its slower release rate, lump sulfur may be better suited for long-term soil amendment and maintenance, rather than providing an immediate source of sulfur for plants.

.

It’s worth noting that the rate of release of sulfur can also depend on the specific type and grade of sulfur being used, as well as the application method and other factors.

Therefore, the specific rate of release of sulfur can vary depending on the specific circumstances and intended use.

.

Cost

The cost of granular sulfur is typically higher than lump sulfur because granular sulfur is often produced in smaller quantities and with additional processing steps to achieve the desired physical form and size for use as a soil amendment.

In contrast, lump sulfur is often used in industrial applications and may require less processing, resulting in a lower cost.